When a pill, a jar of lotion, or a ready-to-eat meal leaves a factory, no one should wonder if it’s safe. That’s not luck. It’s environmental monitoring-a quiet, relentless system of checks that stops contamination before it ever touches the product. In manufacturing, especially in pharmaceuticals, food, and cosmetics, this isn’t optional. It’s the line between a recall and a reputation.

What Environmental Monitoring Actually Does

Environmental monitoring isn’t just cleaning surfaces and hoping for the best. It’s a science. You take samples-swabs from machines, air traps near packaging lines, water from rinse systems-and test them for things that shouldn’t be there: bacteria like Listeria or Salmonella, mold spores, metal particles, even invisible chemical residues. The goal? Catch problems before they reach consumers. The U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) treat this like a safety net. If you skip it, you risk shutdowns, fines, or worse. In 2022, the USDA estimated foodborne illnesses tied to poor environmental controls cost the U.S. economy $77.7 billion. That’s not just money-it’s hospital beds, lost lives, and broken trust.The Zone System: How Facilities Divide Risk

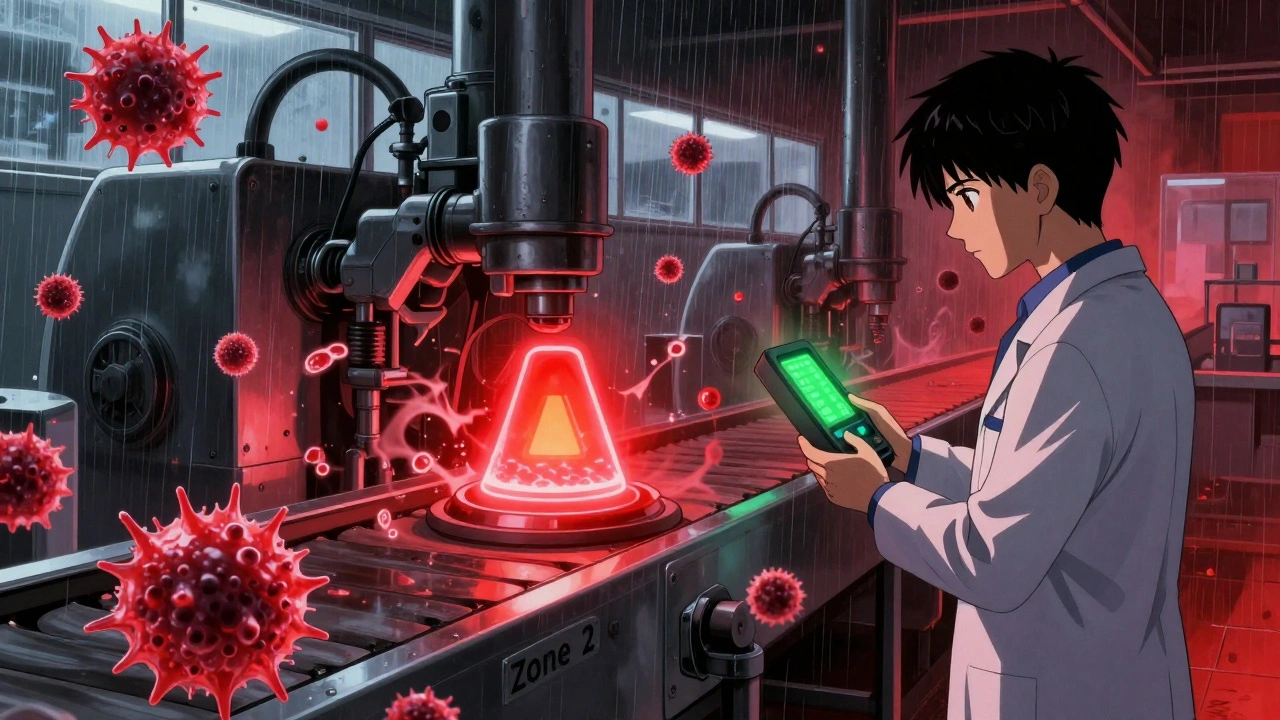

Every facility that does this right uses the same map: the Zone Classification System. It breaks down the factory into four risk levels.- Zone 1: Direct contact with the product. Think slicers, mixing blades, filling nozzles. This is ground zero. If a pathogen lands here, it’s in your product.

- Zone 2: Surfaces near Zone 1 but not touching the product. Conveyor belts, refrigeration units, equipment housings. Contamination here can drift or splash into Zone 1.

- Zone 3: Remote areas in the production zone. Forklifts, tool carts, overhead pipes. Sounds low-risk? Not always. A 2013 study found floors (Zone 3) were responsible for 62% of all contamination alerts.

- Zone 4: Outside production areas-break rooms, storage, hallways. Still monitored, but less frequently.

How Testing Works: Tools and Techniques

Different contaminants need different tools.- Microbial testing: Swabs and air samplers collect bacteria and mold. Results come back in 24 to 72 hours. That’s too slow for fast-moving lines.

- ATP testing: This checks for organic residue-dirt, sweat, food bits-by measuring adenosine triphosphate. It gives results in seconds. Facilities using ATP see production downtime drop by 32% because they can clean and restart faster.

- Air sampling: Liquid impingers and solid impactors pull in large volumes of air. They count how many microbes or particles are in each cubic meter. Critical in cleanrooms where even a single spore can ruin a batch.

- Water testing: For pharmaceuticals, purified water must meet USP <645> standards. Conductivity and total organic carbon (TOC) levels are checked constantly. Food plants check for EPA compliance instead.

- Chemical detection: HPLC and GC machines spot traces of cleaning agents or lubricants that shouldn’t be in the product.

Who Follows the Rules-and Who Doesn’t

Not all industries play by the same rules. Pharmaceutical facilities are the strictest. Under EU GMP Annex 1 (updated in 2023), they must monitor air quality continuously in Grade B cleanrooms. That’s like a hospital operating room-particle counts, temperature, humidity-all tracked in real time. Over 98% of big pharma companies have formal programs. Food manufacturers? Only 76% do. But it’s changing. The USDA’s Listeria Rule (9 CFR Part 430) forces RTE (ready-to-eat) food plants to test Zone 1 surfaces weekly for Listeria monocytogenes. If they don’t, inspectors shut them down. Cosmetics are catching up. The FDA doesn’t have a dedicated rule yet, but if a product causes illness, the company is liable. So most big brands do full environmental monitoring anyway.What Goes Wrong-and How to Fix It

Even with good intentions, things break down.- Sampling mistakes: A swab touches the floor before it touches the machine? Contaminated sample. CDC says 68% of facilities mess up sampling technique. Training is non-negotiable. FDA recommends 40 hours of hands-on practice.

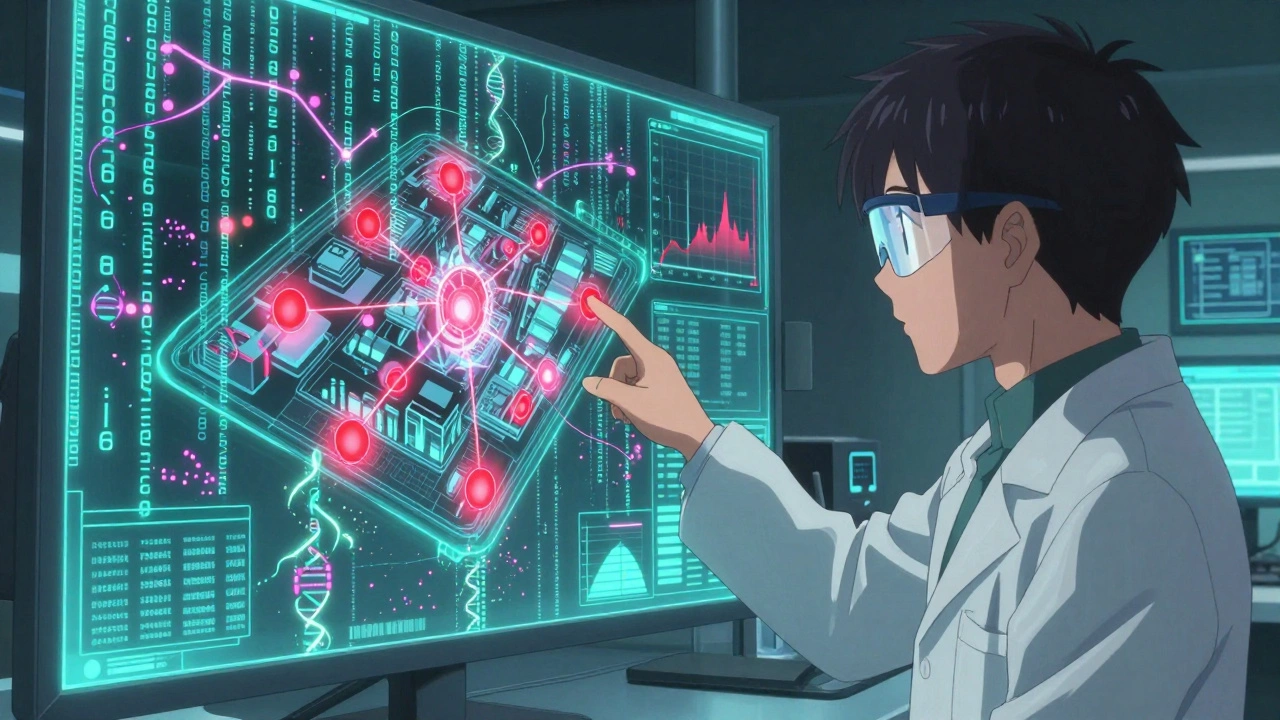

- Too much data, no insight: Many labs run ATP, microbiological, and allergen tests-but never connect the dots. Data stays in silos. AI tools now help tie it together, spotting patterns across weeks or months.

- Under-resourcing: A medium-sized food plant spends $15,000-$25,000 a year on testing and employs 2-3 full-time staff just for monitoring. Small facilities (<50 employees) often skip it. Only 48% of small processors are fully compliant.

- False confidence: Just because you haven’t found contamination doesn’t mean it’s not there. A 2017 study showed that combining environmental data with culture contamination tracking reduced false positives by 27%.

Why This Matters More Than Ever

The market for environmental monitoring hit $7.2 billion in 2022 and is projected to hit $12.5 billion by 2027. Why? Because regulators aren’t backing down. The FDA’s Food Safety Modernization Act (FSMA) turned prevention into law. The EU’s 2023 Annex 1 update demands real-time data trending. Antimicrobial-resistant pathogens are showing up in environmental samples-19% of Listeria strains now resist multiple antibiotics. This isn’t just about compliance. It’s about survival. A single contamination event can cost a company millions in recalls, lawsuits, and lost customers. But a strong environmental monitoring program? It builds trust. It keeps people safe. And it keeps factories open.Where It’s Headed

The future is faster, smarter, and more connected. - AI will analyze months of sampling data to predict where contamination is likely next. By 2027, 38% of systems will use AI-up from 12% in 2022. - Real-time sensors will alert staff the moment air quality dips or a surface gets too humid. - Blockchain-style logs will track every swab, every result, every correction-so auditors can see the full story in seconds. The goal isn’t perfection. It’s control. You can’t eliminate every microbe. But you can know where they are, how they get there, and stop them before they hurt anyone.What is the main purpose of environmental monitoring in manufacturing?

The main purpose is to detect and control contamination-like bacteria, mold, chemicals, or particles-before it gets into products. It’s not about cleaning after the fact. It’s about proving your process is safe, preventing recalls, and protecting public health.

Which zones need the most frequent testing in a food processing plant?

Zone 1 surfaces-those that directly touch food-need daily or weekly testing. Zone 2 surfaces, like nearby equipment or conveyors, are tested weekly to monthly. Zone 3 and 4 areas are sampled less often, but still regularly, because even remote surfaces can be sources of contamination.

Why is ATP testing used alongside microbial swabs?

ATP testing gives results in seconds and shows how clean a surface is by detecting organic residue. Microbial swabs take 24-72 hours to grow cultures and confirm live pathogens. Using both lets you verify sanitation quickly (ATP) and confirm safety (microbial). Facilities that use ATP reduce downtime by up to 32%.

Are environmental monitoring requirements the same for pharmaceuticals and food?

No. Pharmaceutical facilities must meet stricter air quality standards-like ISO Class 5 or EU Grade B-and monitor temperature, humidity, and particles continuously. Food plants focus more on pathogens like Listeria and Salmonella, especially in ready-to-eat products. Water testing also differs: pharma uses USP <645> standards; food follows EPA rules.

How often should environmental monitoring be done?

It depends on the zone and risk. Zone 1: daily to weekly. Zone 2: weekly to monthly. Zone 3: monthly. Zone 4: quarterly. High-risk products like ready-to-eat foods or sterile injectables require more frequent testing. Regulatory agencies like the FDA and USDA set minimums, but best practice often exceeds them.

What are the biggest mistakes facilities make with environmental monitoring?

The top three: inconsistent zone classification, poor sampling technique (like touching swabs to dirty surfaces), and not integrating data from ATP, microbiological, and allergen tests. Many facilities collect data but never analyze trends, so they miss early warning signs.

Can small manufacturing facilities afford environmental monitoring?

Yes, but it’s harder. Medium-sized food plants spend $15,000-$25,000 a year and need 2-3 dedicated staff. Small facilities (<50 employees) often struggle-only 48% are fully compliant. Start small: focus on Zone 1, use ATP for quick checks, outsource lab testing, and train staff properly. It’s cheaper than a recall.

Write a comment

Your email address will not be published.

14 Comments

Environmental monitoring as a predictive control system is fundamentally a feedback loop grounded in stochastic process modeling. The Zone Classification paradigm, while heuristic, approximates a Markovian state transition matrix where contamination probability is a function of spatial proximity and temporal exposure. ATP bioluminescence serves as a proxy for metabolic activity, but its correlation with pathogenic load remains non-linear and context-dependent. NGS integration represents a paradigm shift from culture-based detection to genomic surveillance-this is not merely an upgrade but an ontological redefinition of what 'contamination' means in industrial microbiology.

They say 'no one wonders if it’s safe'-but they also say 'trust the system' while cutting inspection budgets by 40% since 2020. The real story isn’t the swabs. It’s the spreadsheet that says 'pass' because the lab technician was too tired to calibrate the impinger that morning.

Zone 3 is overrated. Floors dont cause 62% of issues. Its the damn managers who dont train staff proper. My cousin work in pharma and he say most fail cause of lazy people not bad tech.

Of course you're all just ignoring the fact that these 'safety protocols' are just corporate theater. The real contamination happens when executives approve cheaper suppliers to boost quarterly earnings. You think they care about Listeria? They care about stock prices. People die because someone's bonus depends on cutting corners. And now you're all just debating swabs like it's a science fair project. Pathetic.

🚨 THIS IS WHY WE CAN’T HAVE NICE THINGS 🚨

Zone 1 gets daily swabs? Great. But who’s cleaning the coffee machine in Zone 4? That’s where the real biofilm is. And don’t get me started on the guy who sneezes into his glove before handling the packaging tape. 😷

ATP testing changed everything for my plant. We went from 3 shutdowns a month to one every 6 weeks. No more guessing. Just green light, move on. Simple. Fast. Life saver.

Wait-so you’re telling me the U.S. government is okay with food plants testing weekly for Listeria… but cosmetics? No rules? That’s not freedom. That’s negligence dressed up as deregulation. We’re letting corporations play Russian roulette with our skin cream. And you’re all nodding like this is normal?

NGS is overhyped. DNA sequencing takes 24 hours? So what? Product is already shipped. Culture methods are slow but reliable. You don’t need fancy machines to know if something smells wrong. The human nose is still the best sensor in the room. And cheaper too.

It is not sufficient to merely comply with regulatory minimums. True excellence in environmental monitoring requires a culture of obsessive vigilance-a non-negotiable standard that transcends audit checklists. One compromised swab is not a statistical anomaly; it is a moral failure.

Look, I get it. We need safety. But let’s be real-when was the last time you heard of someone getting sick from a pill? Meanwhile, we’re spending millions to monitor air in cleanrooms while kids in Detroit drink lead water. Priorities, people. We’re solving the wrong problem.

my coworker just told me they stopped testing zone 3 last year. said it was 'not cost effective'. i dont know what to say. i just hope no one gets sick because of it.

For anyone new to this: zone classification isn’t about rigid labels-it’s about risk-based logic. If your Zone 2 is actually acting like Zone 1, reclassify it. Don’t just follow the template. Understand why the zones exist. And if your team can’t explain the difference between ATP and HPLC in under 60 seconds? You’ve got training gaps. Fix them before the next audit.

Thank you for writing this. I’ve worked in food manufacturing for 12 years and no one ever explains this stuff to outsiders. It’s not glamorous, but it’s what keeps your kid’s cereal safe. The people doing the swabs? They’re the quiet heroes. We don’t talk about them enough.

Let’s not pretend this is about safety. It’s about liability. The FDA doesn’t care if you’re clean-they care if you can prove you’re clean. The moment a child dies from a contaminated product, the entire industry becomes a target. That’s why you see the spending spike. Not because of ethics. Because of lawsuits. And don’t be fooled-the real surveillance isn’t in the cleanroom. It’s in the legal department.